Plastic Bins

-

-

Flat drop on Lid for stacking bins 30x20cm

Price From €2.00 -

Flat drop on Lid for stacking bins 40x30cm

Price From €3.45 -

Insert tray 1/8 dimension 18x14x5cm for stacking bins 60x40cm

Price From €2.20 -

Insert bin 1/4 for stacking bins 60x40 cm

Price From €2.98 -

Insert bin 1/8 for stacking bins 60x40 cm

Price From €2.35 -

Stacking bin 30x20x12cm, capacity 5,3 litres

Price From €3.70 -

Flat drop on Lid for stacking bins 60x40cm

Price From €4.60 -

Euro stacking bin 40x30x12cm, capacity 10 litres, transparent

Price From €6.30 -

Stacking bin 30x20x17cm, capacity 7,6 litres

Price From €5.40 -

Stacking bin 40x30x12cm, capacity 10 litres, black

Price From €4.95 -

ESD stacking bin 30x20x12cm, capacity 5,3 liters

Price From €6.10 -

Insert bin 1/4 for stacking bins 60x40cm

Price From €3.40 -

Stacking bin 40x30x7,5cm, capacity 6,9 litres

Price From €4.40 -

ESD Insert bin 1/2 for stacking bins 40x30 cm

Price From €3.90 -

Stacking bin 40x30x17cm, capacity 15 litres, black

Price From €5.90 -

Top divider with 24 compartments, Ø 8.5 cm (4.55" inch)

Price From €4.90 -

Bottom divider with 24 compartments, Ø 8.5 cm (4.55 inch")

Price From €4.90 -

Top divider with 15 compartments, Ø 10.8 cm (4.55" inch)

Price From €5.80 -

Bottom divider with 15 compartments, Ø 10.8 cm (4.25" inch)

Price From €5.80 -

ESD stacking bin 30x20x17cm, capacity 7,57 liters

Price From €6.20 -

Brackets bin 30x20x17cm, capacity 8 liters

Price From €5.70 -

Flat ESD lid for stacking bins 60x40cm

Price From €4.95 -

Nestable bin 30x20x17cm, capacity 8 liters

Price From €4.76 -

Insert bin 1/4 for stacking bins 60x40 cm

Price From €4.55 -

Stacking bin 40x30x12cm, capacity 10 litres, red

Price From €6.45 -

Stacking bin 40x30x12cm, capacity 10 litres

Price From €6.45 -

ESD stacking bin 40x30x7.5cm, capacity 6.9 liters

Price From €6.89 -

ESD stacking bin 40x30x7,5cm, capacity 6,9 liters

Price From €6.89 -

Top divider with 40 compartments, Ø 6.5 cm

Price From €5.40 -

Bottom divider with 40 compartments, Ø 6.5 cm (2.55" inch)

Price From €5.40 -

Stacking bin 40x30x22cm, capacity 20 litres, black

Price From €6.70 -

Nestable tray 35,5x26x4 cm, capacity 3 liters

Price From €6.65 -

Inzetbak 1/2 afmeting 26x18x15cm voor stapelbakken 40x30cm

Price From €4.05 -

Nestable bin 40x30x22cm, capacity 18 liters

Price From €4.90 -

Order picking bin 30x20x17cm, capacity 7,6 liter

Price From €5.80 -

Top divider with 12 compartments, Ø 11.6 cm (4,57 inch)

Price From €5.10 -

Bottom divider with 12 compartments, Ø 11.6 cm (4,57 inch)

Price From €5.10 -

Stacking crate 60x40x7,5cm, 13 Liter

Price From €6.50 -

Nestable bin 40x30x27cm, capacity 22 liters

Price From €5.90 -

ESD stacking bin with hinged lid 30x20x13,5cm, capacity 4,45 liter

Price From €6.57 -

Stacking bin 60x40x12cm, capacity 20 litres, black

Price From €7.45 -

Stacking bin 40x30x12cm, capacity 10 litres, yellow

Price From €6.85 -

Stacking bin 40x30x12cm, capacity 10 litres, green

Price From €6.85 -

Stacking bin 40x30x12cm, capacity 10 litres, blue

Price From €6.85 -

Stacking bin 60x40x7,5cm, capacity 15 litres

Price From €7.10 -

Bin with hinged lid 30x20x19cm, capacity 5,2 liters

Price From €7.15 -

Stacking bin, 60x40x5,5cm, capacity 9 liters, HDPE

Price From €6.80 -

Euro stacking bin 40x30x22,5cm, capacity 21 litres, transparent

Price From €8.05 -

Stacking bin 54x36x11.5cm, capacity 12 liters with lugs

Price From €9.65 -

ESD stacking bin 40x30x12 cm, capacity 10 liters

Price From €7.80 -

Nestable bin 40x30x32cm, capacity 26 liters

Price From €6.90 -

Stacking bin 60x40x7,5cm, capacity 14 liters

Price From €6.85 -

ESD stacking bin 60x40x7,5 cm, capacity 15 liters

Price From €8.95 -

ESD stacking bin 40x30x17 cm, capacity 15 liters

Price From €9.30 -

Stacking crate 60x40x12cm, 22 Liter

Price From €9.10 -

Stacking bin 40x30x22cm, capacity 20 litres

Price From €8.15 -

Stacking bin 40x30x22cm, capacity 20 litres

Price From €8.15 -

Stacking crate 60x40x15cm, 28 Liter

Price From €10.30 -

Stacking crate 60x40x12,5cm, capacity 21 litres

Price From €9.30 -

Stacking bin 60x40x17cm, capacity 33 litres, black

Price From €8.70 -

ESD stacking bin 40x30x22 cm, capacity 20 litres

Price From €9.60 -

Order picking bin 40x30x27cm, capacity 26 liters

Price From €6.45 -

Stacking bin 40x30x32,5cm, capacity 30 litres, black

Price From €8.90 -

Stacking bin 60x40x12cm, capacity 24 litres

Price From €9.60 -

Stacking bin 60x40x12cm, capacity 24 litres

Price From €9.60 -

Stacking bin 40x30x17cm, capacity 15 litres

Price From €8.40 -

Stapelbak 40x30x17cm, inhoud 15 liter, groen

Price From €9.30 -

Stacking bin 40x30x17cm, capacity 15 litres, red

Price From €9.30 -

Stacking bin 40x30x17cm, capacity 15 litres, yellow

Price From €9.30 -

Filet box 50x40x11cm, capacity 8 liters with drainage holes

Price From €8.90 -

Stacking bin 40x30x17cm, capacity 15 litres, blue

Price From €9.30 -

Stacking crate 60x40x17cm, 33 Liter

Price From €11.30 -

Nestable bin 60x40x17cm, capacity 29 liters

Price From €7.95 -

Stacking bin 40x30x27cm, capacity 26 litres

Price From €10.60 -

Stacking bin 40x30x27cm, capacity 26 litres

Price From €10.60 -

Brackets bin 40x30x22cm, capacity 18 liters

Price From €6.20 -

Order picking bin 40x30x22cm, capacity 20 liters

Price From €8.80 -

Stacking bin 40x30x22cm, capacity 20 litres, red

Price From €10.15 -

Stacking bin 40x30x22cm, capacity 20 litres, blue

Price From €10.15 -

Order picking bin 30x20x17cm, capacity 7,6 liter

Price From €7.75 -

Stacking bin with lid 30x20x13,5cm, capacity 4,45 liters

Price From €8.17 -

Stacking bin 60x40x12cm, capacity 20 litres, yellow

Price From €11.50 -

Stacking bin 60x40x12cm, capacity 20 litres, green

Price From €11.50 -

Stacking bin 60x40x12cm, capacity 20 litres, red

Price From €11.50 -

Stacking bin 60x40x12cm, capacity 20 litres, blue

Price From €11.50 -

Folding Crate 60x40x23cm, capacity 44 litres, Distri-Box

Price From €9.95 -

Nesting bin 44x32,5x15,5cm, capacity 12 liters, smooth design

Price From €10.10 -

ESD stacking bin with hinged lid 30x20x18,5 cm, capacity 7,57 liter

Price From €6.20 -

Euro stacking bin 60x40x12,5cm, capacity 24 litres, transparent

Price From €8.60 -

Stacking bin 40x30x7,5cm, capacity 6,9 litres

Price From €7.65 -

Fish box 60x40x12,5cm, capacity 15 liters with drainage holes

Price From €8.80 -

Order picking bin 40x30x32cm, 30 liter

Price From €7.45 -

Stacking bin 60x40x22cm, capacity 45 litres, black

Price From €10.15 -

Stacking bin with lid 30x20x18,5cm, capacity 7,57 liters

Price From €8.90 -

Stacking crate 60x40x20cm, 40 Liter

Price From €9.75 -

Stacking crate 60x40x20cm, capacity 40 litres

Price From €9.75 -

Stacking crate 60x40x20cm, capacity 40 litres

Price From €9.75 -

Stacking crate 60x40x20cm, capacity 40 litres

Price From €9.75 -

ESD stacking bin 40x30x27 cm, capacity 26 liters

Price From €11.70 -

Stacking crate 60x40x20cm, capacity 40 litres

Price From €9.85 -

Nesting bin 51x34,5x12cm, capacity 12 liters, smooth design

Price From €8.75 -

Stacking bin, 40x30x16,5cm, capacity 12 liters

Price From €8.70 -

ESD stacking bin 60x40x12cm, capacity 24 liters

Price From €11.40 -

Nestable bin 60x40x22cm, capacity 36 liters

Price From €8.90 -

Stacking bin 40x30x32cm, capacity 30 litres

Price From €12.05 -

Stacking bin 40x30x32cm, capacity 30 litres

Price From €12.05 -

Stacking bin 60x40x17cm, capacity 35 litres

Price From €12.20 -

Stacking bin 60x40x17cm, capacity 35 litres

Price From €12.20 -

Stacking bin 60x40x17cm, capacity 33 litres, yellow

Price From €13.05 -

Stacking bin 60x40x17cm, capacity 33 litres, green

Price From €13.05 -

Stacking bin 60x40x17cm, capacity 33 litres, red

Price From €13.05 -

Stacking bin 60x40x17cm, capacity 33 litres, blue

Price From €13.05 -

ESD stacking bin with hinged lid 40x30x9 cm, capacity 5,2 liter

Price From €8.90 -

Brackets bin 40x30x27cm, capacity 22 liters

Price From €7.30 -

Stacking bin 60x40x27cm, capacity 54 liters, black

Price From €9.20 -

Bin with hinged lid 40x30x24cm, capacity 18 liters

Price From €9.90 -

Fish box 60x40x15,5cm, capacity 20 liters with drainage holes

Price From €8.50 -

Stack and nesting bin 60x40x22cm, capacity 35 liters

Price From €9.30 -

Stacking bin 45x25,5x11cm, capacity 8 liters, smooth design

Price From €10.30 -

Stacking bin 40x30x32cm, capacity 30 litres, green

Price From €13.85 -

Stacking bin 40x30x32,5cm, capacity 30 litres, blue

Price From €13.85 -

Stacking bin 60x40x22cm, capacity 45 litres, yellow

Price From €14.90 -

ESD stacking bin 40x30x32 cm, capacity 30 liters

Price From €13.10 -

Stacking bin, 40x30x21,5cm, capacity 15 liters

Price From €10.50 -

Stacking bin 60x40x22cm, capacity 45 litres, green

Price From €14.90 -

Stacking bin 60x40x22cm, capacity 45 litres, red

Price From €14.90 -

Stacking bin 60x40x22cm, capacity 45 litres, green

Price From €14.90 -

Stack and nesting bin 60x40x27cm, capacity 45 liters

Price From €10.60 -

Stacking crate 60x40x22cm, 43 Liter

Price From €14.30 -

Stacking bin 60x40x22cm, capacity 45 litres

Price From €14.70 -

Stacking bin 60x40x22cm, capacity 45 litres

Price From €14.70 -

Stacking bin 40x30x36cm, capacity 35 litres

Price From €14.55 -

Stacking bin with lid 40x30x9cm, capacity 5,2 liters

Price From €10.05 -

Bin with hinged lid 40x30x29cm, capacity 22 liters

Price From €10.50 -

Stacking bin 60x40x32cm, capacity 66 litres, black

Price From €12.20 -

Stacking bin 46,5x36x8,2cm, capacity 10 liters, smooth design

Price From €11.40 -

Brackets bin 40x30x32cm, capacity 26 liters

Price From €8.50 -

Stacking bin 45x30x12,5cm, capacity 10 liters, smooth design

Price From €10.80 -

Stacking bin 45x30x7cm, capacity 7 liters, smooth design

Price From €10.20 -

Nestable bin 60x40x27cm, capacity 45 liters

Price From €11.50 -

Stacking crate 60x40x27cm, 54 Liter

Price From €15.90 -

Tapered round bin 35 liter heavy duty

Price From €13.90 -

Stack and nesting bin 60x40x20cm, capacity 32 liters

Price From €12.80 -

Nesting bin 61x44x15cm, capacity 25 liters, smooth design

Price From €15.90 -

Stacking bin, 60x40x12cm, capacity 23 liters, HDPE

Price From €13.10 -

Bin with hinged lid 40x30x34cm, capacity 26 liters

Price From €11.70 -

Euro stacking bin 60x40x22cm, capacity 44 liters, Transparent

Price From €14.95 -

Stack and nesting bin 60x40x20cm, capacity 32 liters

Price From €12.90 -

ESD stacking bin 60x40x17 cm, capacity 35 liters

Price From €10.13 -

Glass bin 60x40x7,5cm, with 12 piece compartment base

Price From €12.55 -

-

Glass bin 60x40x7,5cm, with 15 piece compartment base

Price From €12.85 -

Stacking crate 60x40x32cm, 64 Liter

Price From €15.50 -

Stacking bin 58x36x10cm, capacity 15 liters, smooth design

Price From €11.90 -

Stacking bin with lid 60x40x33,5cm, capacity 66 liters

Price From €17.50 -

Nestable stackable bin 62x50x15cm, capacity 25 liters

Price From €16.50 -

Adjustable compartment divider create your own size

Price From €10.90 -

Stacking bin 60x40X17cm, capacity 33 litres, HDPE

Price From €15.70 -

Glass bin 60x40x7,5cm, with 24 piece compartment base

Price From €13.15 -

Stacking box with curved lips, 60x40x16,5cm capacity 20 liters

Price From €14.90 -

Stacking bin with lid 40x30x18,5cm, capacity 15 liters

Price From €13.30 -

Stacking bin with lid 40x30x18,5cm, capacity 15 liters

Price From €13.00 -

Order picking bin 60x40x27cm, capacity 56 liters with large grab opening

Price From €11.00 -

Order picking bin 40x30x22cm, capacity 20 liters

Price From €11.80 -

Stacking bin 60x40x27cm, capacity 56 litres

Price From €17.90 -

Stacking bin 60x40x27cm, capacity 56 litres

Price From €17.90 -

Brackets bin 60x40x17cm, capacity 29 liters

Price From €14.90 -

Order picking bin 40x30x27cm, capacity 26 liters

Price From €14.40 -

Glass bin 60x40x12cm, with 12 piece top compartment

Price From €13.80 -

Nestable stackable bin 62x50x15cm, capacity 25 liters

Price From €17.20 -

Nestable stackable bin 62x50x15cm, capacity 25 liters

Price From €17.20 -

Glass bin 60x40x7,5cm, with 40 piece compartment base

Price From €13.98 -

ESD stacking bin 60x40x22 cm, capacity 45 liters

Price From €13.55 -

Glass bin 60x40x12cm, with 15 piece compartment base

Price From €14.10 -

Stacking bin 40x30x27cm, capacity 26 litres

Price From €14.15 -

Stacking bin 60x40X20cm, capacity 40 litres, HDPE

Price From €15.90 -

Glass bin 60x40x15cm, with 12 piece top compartment

Price From €13.95 -

Glass bin 60x40x12cm, with 24 piece top compartment

Price From €14.85 -

Stacking bin with lid 40x30x23,5cm, capacity 20 liters

Price From €14.95 -

Stacking bin with lid 40x30x23,5cm, capacity 20 liters

Price From €14.95 -

Glass bin 60x40x15cm, with 24 piece top compartment

Price From €14.60 -

Stacking bin 52x45,5x11cm, capacity 18 liters

Price From €14.70 -

Order picking bin 60x40x17cm, 35 liter

Price From €15.85 -

Order picking bin 60x40x22cm, 45 liter

Price From €17.15 -

Stacking bin 60x40x32cm, capacity 66 litres

Price From €17.80 -

Stacking bin 60x40x32cm, capacity 66 litres

Price From €17.80 -

Euro stacking bin 60x40x32cm, capacity 66 liters, Transparent

Price From €15.20 -

Stacking bin 60x40X30cm, capacity 60 litres, - HDPE - Heavy Duty

Price From €14.95 -

Nestable bin 60x40x32cm, capacity 54 liters

Price From €12.30 -

Folding bin 60x40x22cm, capacity 38 liters

Price From €15.60 -

Folding bin 60x40x27cm, capacity 56 liters

Price From €16.50 -

Folding bin 60x40x32cm, capacity 58 liters

Price From €17.50 -

Stack and nesting bin 60x40x20cm, capacity 25 liters

Price From €18.15 -

Glass bin 60x40x15cm, with 15 piece top compartment

Price From €15.30 -

Stacking bin with lid 40x30x28,5cm, capacity 26 liters

Price From €16.40 -

Stacking bin with lid 40x30x28,5cm, capacity 26 liters

Price From €16.40 -

Glass bin 60x40x12cm, with 40 piece top compartment

Price From €15.20 -

Bin with hinged lid 60x40x32cm, capacity 54 liters

Price From €12.90 -

Folding bin with lid 60x40x22cm, capacity 38 liters

Price From €15.90

Plastic Bins, Storage Containers, Stacking Boxes and Transport Crates, NORAH Plastics' extensive assortment of Euro-sized transport and storage products are durable, long-lasting and produced from food-grade PP or PE material. The stacking bins are available in various colors, sizes and options. Compatible with other Euro-size stacking bins, pallets, roll containers and transport dollies - Suitable for Industry, Trade, Retail and Commercial sectors.

With over 50 years of experience in developing industrial durable storage and transport systems, NORAH Plastics offers standard solutions that meet most logistics requirements of industrial production segments. If a specific application requires new or customized packaging, our innovation department will design, develop and test a customized packaging solution to meet your needs.

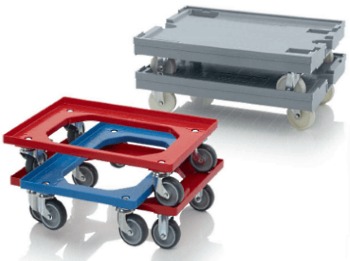

We provide a wide range plastic crates and stacking containers products to meet the storage, handling and distribution needs of all industries – helping our customers to speed handling operations, reduce logistics costs and eliminate packaging waste. Our Solutions include tough stacking containers, tamper-evident attached-lid containers (ALCs) for secure distribution, heavy-duty rigid and folding large containers (FLCs), pallets and dollies - all designed to protect small large or awkwardly shaped components, speed delivery of goods and, with foldable or stackable units, save valuable space on return journeys. Manufactured to precise dimensions, to fit and function seamlessly with all handling equipment.

Our containers are the ideal handling medium for automated warehouses and distribution centers. They promote a reliable and consistent flow, withstanding heavy unit loads and allow fast movement through automated storage and retrieval systems. With more than 50 years experience in developing industrial reusable packaging NORAH Plastics offers standard solutions that meet most industrial manufacturing segments logistics requirements. Should a specific application require new or bespoke packaging, our innovation department will design, develop and test a customized reusable packaging solution to meet your needs.

What is the difference between plastic bins and plastic crates?

For example, plastic bins that have a hinged lid with latches or hinged lid. A large grab opening on the short or long side for quick access to stored products. Or locking the plastic bin by fitting a key lock to prevent unauthorized opening. Even more efficiency? Then better equip the bins with plastic inserts for optimal plastic bin layout.

What versions are available?

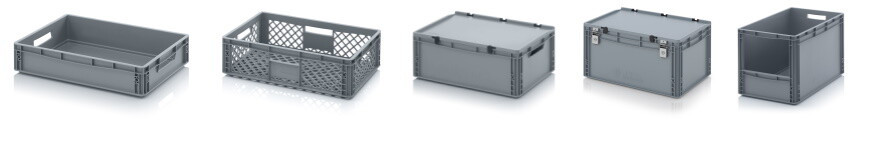

Present day there are several models available, not only in design but also in execution.

|

|

|

|

|

|

|

|

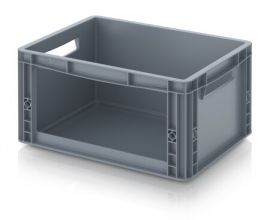

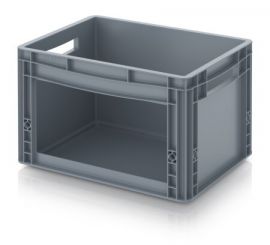

- Conventional stacking bin, a classic design, practical and simple.

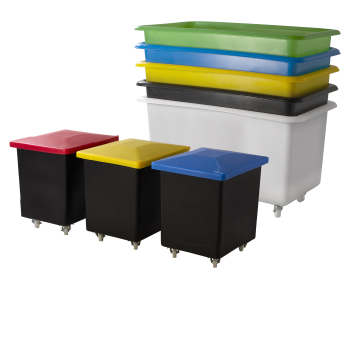

- Logistic bins, also called distribution bins for transport or warehouse applications, stackable and nestable with hinged lid or stacking brackets.

- Food bins for preparation, processing or production of foodstuffs, raw materials and medicines.

- ESD stacking bins protect sensitive electronic parts, chips and electrical components from static charges.

- Stackable and nestable bins for space-saving storage and transport.

- Warehouse bins with open front to create overview and efficiency in a warehouse, workshop or assembly department.

- Order Pick stacking bins with a large grab opening for orderly storage and quick access to different products up to the bottom bin.

- Tilting bins are transparent bins; this allows you to keep a complete overview at all times. You can immediately see what is stored in the transparent tipping bin.

Euronorm stacking bins, exactly according to your requirements!

You can choose from various basic Euronorm sizes, closed plastic stacking bins are available up to a height and size of 80x60x52cm, perforated stacking bins have the standard Euronorm size of 60x40cm and are available in variable heights up to 42 cm. KLT bins and the ESD stacking bins are available up to a height and dimensions of 80x60x55cm. In addition, a choice of different RAL colors is available upon request - thus each plastic stacking bin can be optimally integrated into your storage and transport process. For conventional standard stacking bins as well as KLT bins and the ESD stacking bins, matching lids, transport dollies and plastic pallets are available that enable optimal and safe stacking or transport of palletized goods.

Application options plastic bins, plastic crates and warehouse bins.

The conventional stacking bin, a classic version, practical and simple "BASIC LINE" is a closed Euronorm stacking bin. It is characterized in particular by its wide range of sizes and is therefore universally applicable. A stacking bin with hinged lid provides additional protection for your goods. The perforated plastic crates is ideally suited for storing and transporting contents that need to be stored cold, for example, because they still contain a certain amount of residual moisture when the crates are filled. Special E1, E2 and E3 meat crates have been developed for the storage and transport of meat and sausage products, which prevent the accumulation of water and are therefore ideally suited for meat handling and food processing. Typical for use in storage and logistics processes in the automotive industry are demo storage bins in various sizes and heights. Due to their unique design, these special plastic bins made of polypropylene fit perfectly into highly automated production processes and are also stackable.

What is the difference between the plastic resource materials polypropylene and polythene?

Polypropylene-PP is a material with high impact resistance and a high temperature range. In addition, the material is lightweight and has high chemical resistance. Add the excellent mechanical product properties such as processing as granules in an injection molding machine makes the Polypropylene-PP material one of the most versatile plastic raw material material material in the packaging industry. Well-known products such as plastic bins, plastic crates, warehouse bins, packaging buckets with lids, or related packaging materials. Polypropylene-PP does not absorb moisture, is even moisture repellent and can be used at temperatures from -20°C to +90°C. Polypropylene is also known in the packaging industry as Polypropylene or abbreviated as PP.

Polyethylene (polyethene) is a crystalline thermoplastic and belongs to the group of polyolefins. This material is mainly used in heavier industrial applications such as the well-known KLIKO waste containers but also plastic pallets, Plastic pallet boxes, plastic barrels are made of HDPE. The material is resistant to sunlight (UV radiation) and other weather influences and can therefore be used permanently outdoors. HDPE does not absorb moisture, is even moisture repellent and can be used at temperatures from -30°C to +60°C. Polyethylene plastic has an apolar surface and can therefore not be glued. However, it can be joined with a hot air welding gun. Polyethylene is also known in the packaging industry as High Density Polyethylene or abbreviated as HDPE.

Do you have a question about our products, or can't find a particular item? Please feel free to contact us.